A design is a plan or specification for the construction of a product or service that should satisfy certain requirements. The aim of design is to maximize the quality of the product given available resources and limitations of constraints. Many constraints exist, such as budget, time, standards, legal, economic, environmental, sustainability, manufacturability, conformability, aesthetics, safety, marketability, ethical, health, safety, socio-political. The potential for failure in a project is minimized by good project management and good design; risks should be identified and plans for managing them should be formulated. The design process can be broken down into a number of steps:

It is sometimes good practice to plan for a minimum viable product (MVP) to be completed early and then if time permits make incremental improvements to the product. This will give time for the team to address unexpected issues and ensure successful completion of the course.

A successful a designer needs to

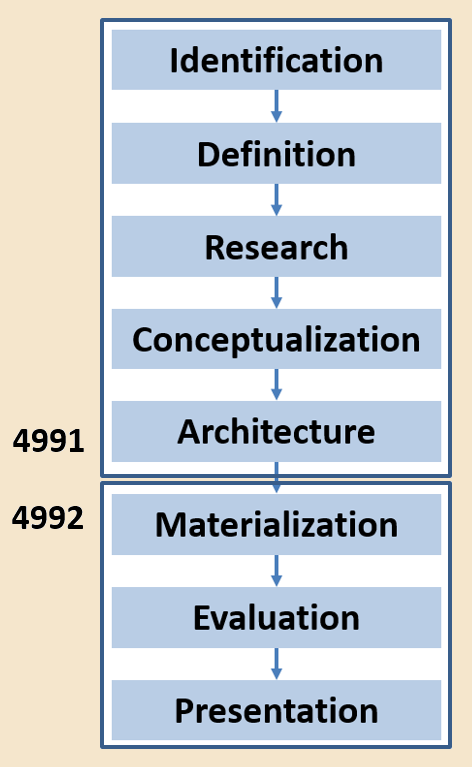

Progression through the 4991 and 4992 courses

The expectation for the

4991 course is that the project team provides by the end of the semester a project proposal

that covers the first five design steps up to and including the physical architecture

(materialization of the product or propotype is not required). The proposal should also

include a full account of how the project is being managed and the plan for executing the

remaining design steps (see lecture Topic 1).

The final three steps of the design process are performed in the 4992 course.